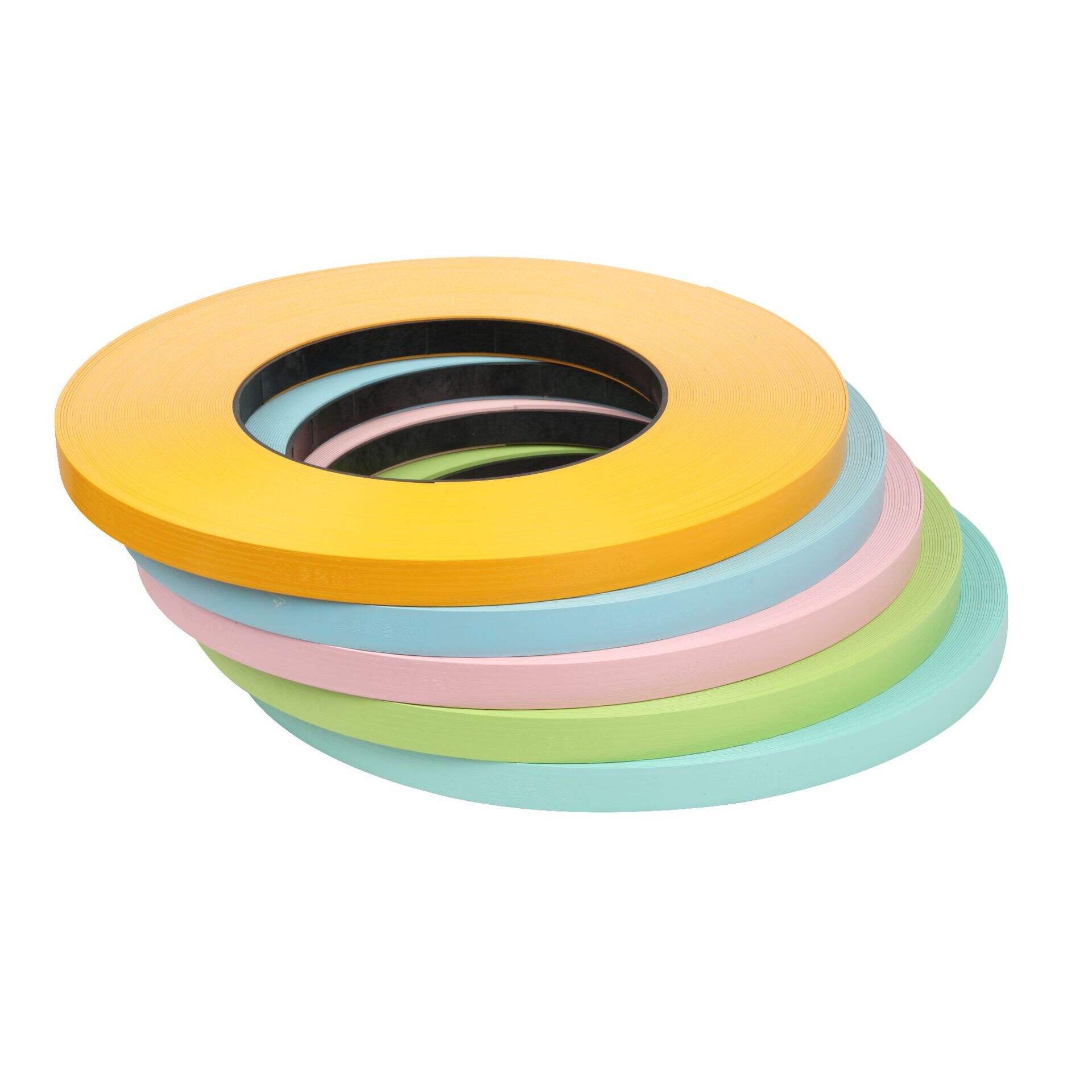

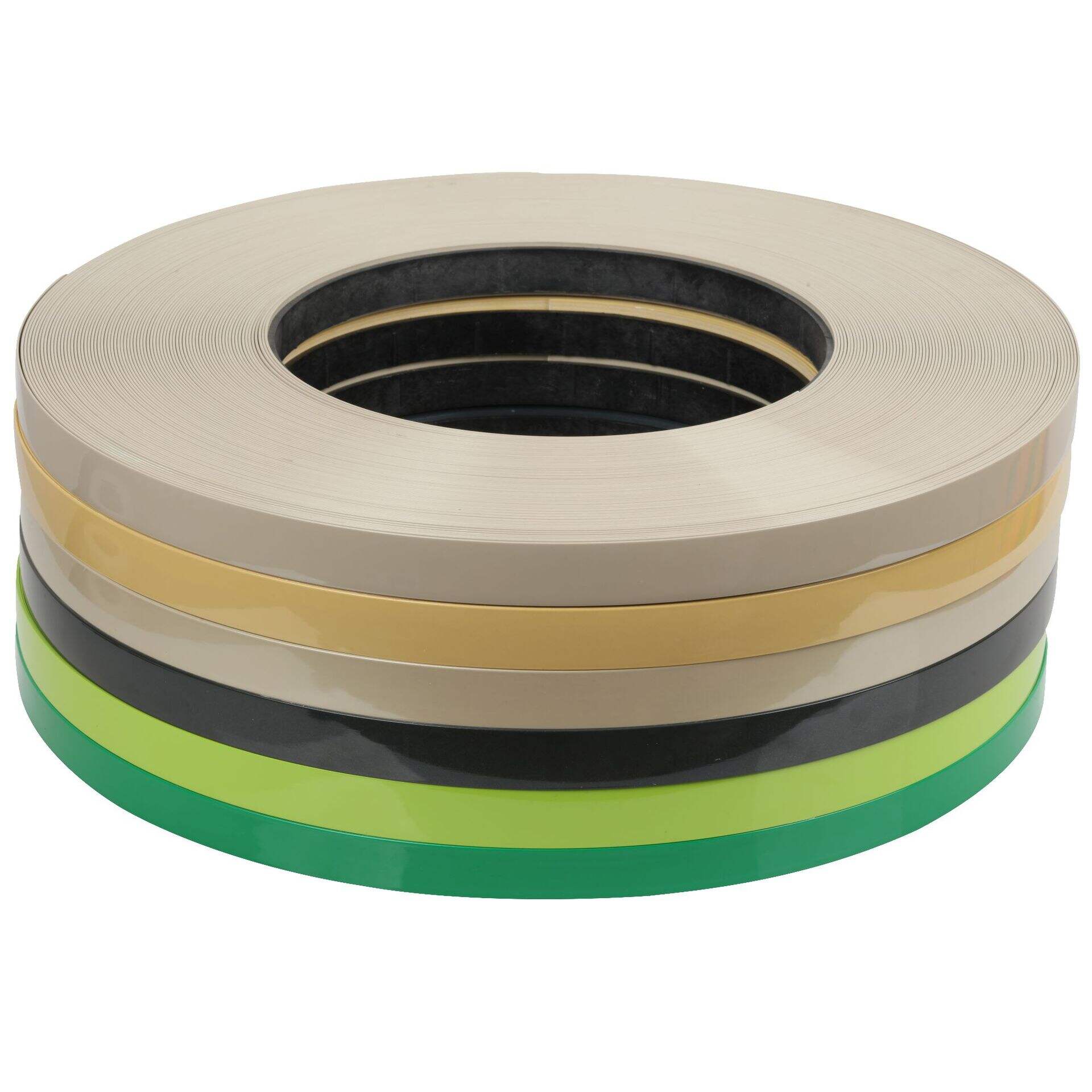

PVC edge banding is primarily composed of polyvinyl chloride (PVC), produced through mixing, calendering, and vacuum forming processes. It is widely used in furniture, office furniture, kitchenware, teaching equipment, and residential laboratories. Thicknesses range from 0.3 to 3mm, and widths from 12mm to 80mm. Key features include a smooth surface, no blistering or streaking, moderate gloss, flat front and back surfaces, uniform thickness, consistent width, optimal hardness, high elasticity, high quality, and strong wear resistance. After trimming, the side color of the edge banding matches the surface color, exhibiting no whitish cast and a high gloss, ensuring a harmonious overall color for the finished furniture.

The primary function of edge banding is to seal the cross-section of the board, protecting it from damage from environmental and operational factors (primarily moisture), preventing formaldehyde from escaping, and achieving a decorative aesthetic.

Egde banding is widely used in furniture, office furniture, kitchenware, teaching equipment, and residential laboratories.

Normally it can be applied to mdf/plywood/chipboard with HPL together, and the color can be matched according to HPL.